Technical Information

Thoroughly Tested, Globally Respected

Barsplice couplers and terminators are recognized across North America and the globe for their performance and reliability. With approval in all 50 states and in Canada, our products are used in a variety of projects and applications. Choose us as your trusted splicing supplier today!

For Technical Support, call 937-275-8700 or email engineering@barsplice.com.

Quality

Each lot of couplers and terminators are tested to verify performance before leaving our warehouse. Detailed material traceability reports will satisfy your project requirements.

Innovation

Using state-of-the-art design tools and years of industry knowledge, our engineering team will collaborate with you to create innovative products tailored to meet your project’s unique demands.

Reliability

Designed, manufactured and tested for proven dependability. Simple shop and field installation means minimal site inspection, allowing your project to stay on schedule.

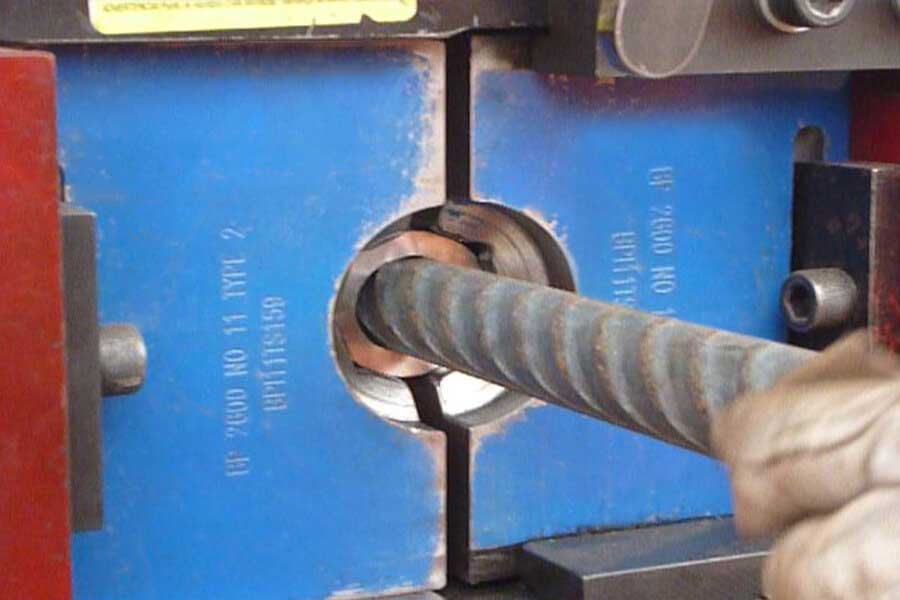

Cold-Swaging Technology

Several of BPI’s products utilize our cold-swaging technology. This process involves using a specialized hydraulic press to compress the coupler or terminator around the rebar. Cold swaging provides a strong, uniform connection that gives unparalleled performance and reliability. This method does not reduce the cross-sectional area of the rebar, but rather adds to it as the coupler is fully formed around the rebar deformations.

Product Lines That Utilize Cold-Swaging

BarGrip XL

Product PageButtonHead

Product PageTaper Threaded Grip-Twist

Product PageTesting Data

Testing Data

BarGrip

Testing Data

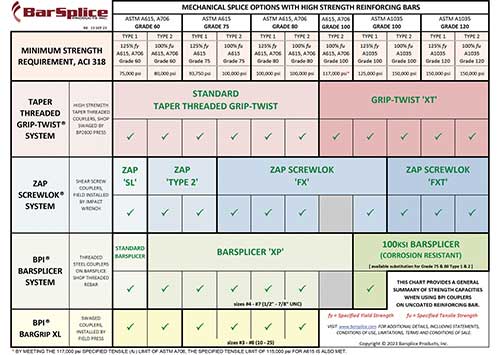

Barsplicer Standard

Testing Data

Barsplicer XP

Testing Data

Barsplicer Stainless

Testing Data

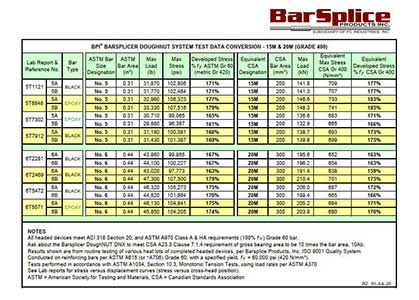

Barsplicer DoughNUT

Testing Data

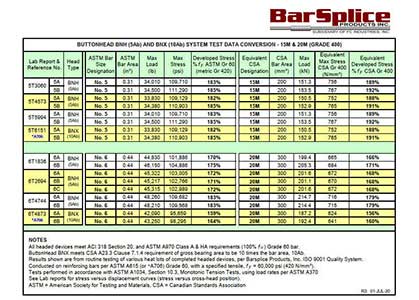

ButtonHead Grade 60

Testing Data

ButtonHead Grade 75/80

Testing Data

ButtonHead Grade 100

Testing Data

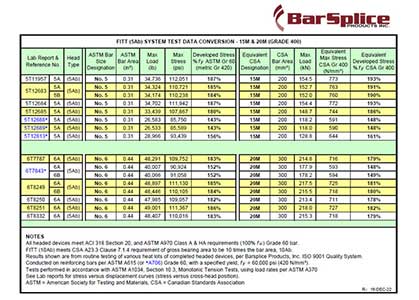

BPI® FITT® Termination Grade 60

Testing Data

BPI® FITT® Termination Grade 75/80

Testing Data

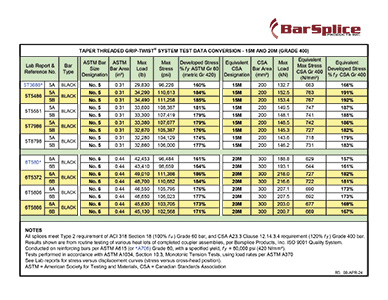

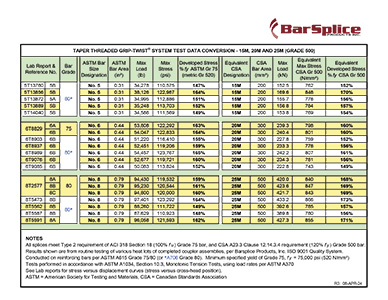

Taper Grip-Twist Grade 60

Testing Data

Taper Grip-Twist Grade 75/80

Testing Data

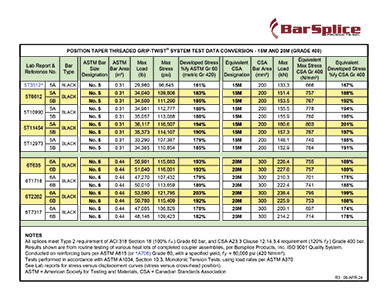

Position Grip-Twist

Testing Data

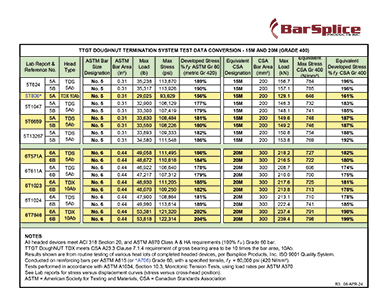

Grip-Twist DoughNUT, TDS, TDX

Testing Data

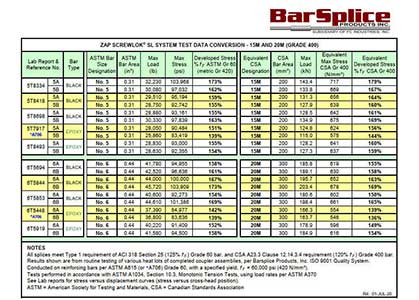

Zap Screwlok SL

Testing Data

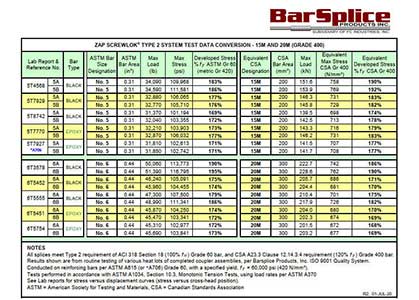

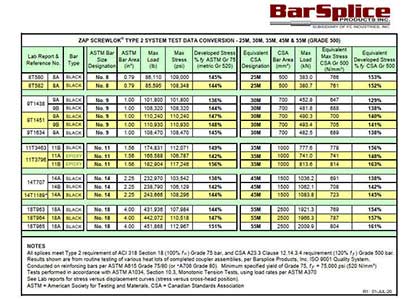

Zap Screwlok Type 2

Testing Data

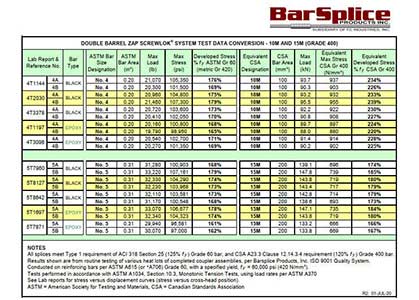

Zap Double Barrel

Testing Data

Zap Screwlok FX

Testing Data

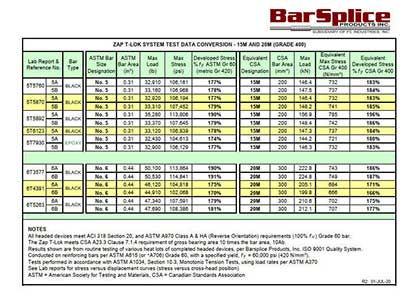

Zap T-lok

Installation Instructions

Installation Instructions

Barsplicer DoughNUT

Installation Instructions

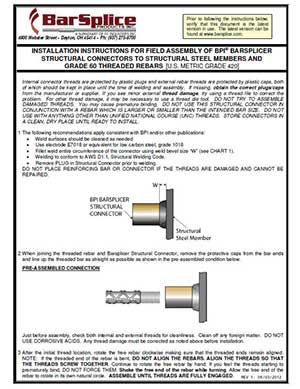

Barsplicer Structural Conn.

Installation Instructions

BPI® FITT® Termination

Installation Instructions

BPI® FITT® Coupler

Installation Instructions

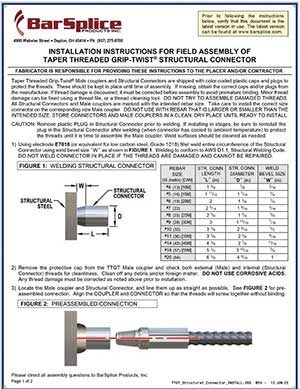

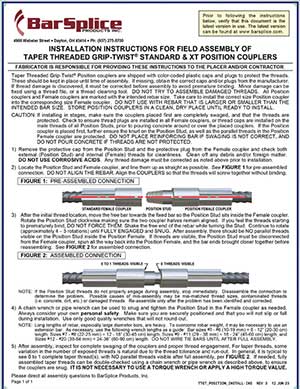

Taper Threaded Grip-Twist

Installation Instructions

Grip-Twist DoughNUT

Installation Instructions

Grip-Twist with Flange

Installation Instructions

Grip-Twist NC Bolt Connector

Installation Instructions

Grip-Twist Structural Connector

Installation Instructions

Grip-Twist to ButtonHead (BNE)

Installation Instructions

Grip-Twist Ultimate (CalTrans)

Installation Instructions

Taper Grip-Twist Position

Installation Instructions

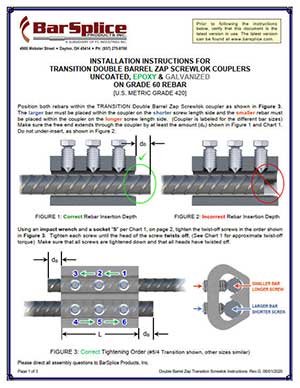

Zap Screwlok Double Barrel

Installation Instructions

Zap Screwlok FX (High Strength)

Installation Instructions

Zap Screwlok #4 - #11 SL

Installation Instructions

Zap Screwlok #14 - #18 SL

Installation Instructions

Zap Screwlok Structural Connector

Installation Instructions

Zap Screwlok #3 - #11 Type 2 & Epoxy Series

Installation Instructions

Zap Screwlok #14 - #18 Type 2 & Epoxy Series

Installation Instructions

Zap Screwlok Transition

Installation Instructions

Zap T-lok

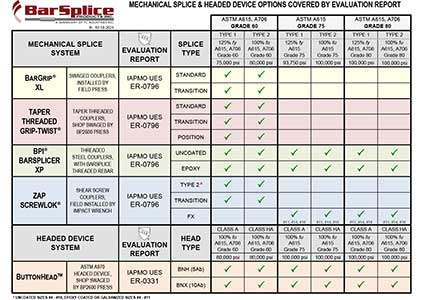

IAPMO/ICC Reports

Evaluation Reports

IAPMO/ICC Report

ER-0796 (BGXL,TTGT,BARSPLICER XP,ZAP - English)

IAPMO/ICC Report

ER-0796 (BGXL,TTGT,BARSPLICER XP,ZAP - español)

IAPMO/ICC Report

ER-0331 (BUTTONHEAD - English)

IAPMO/ICC Report

ER-0331 (ButtonHead - español)

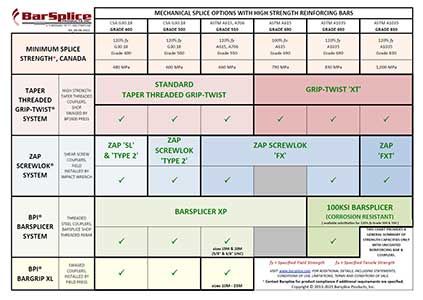

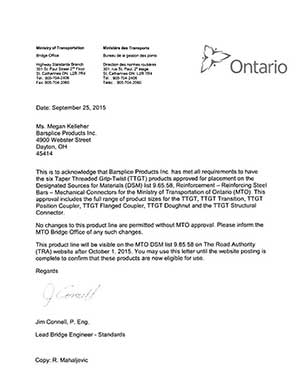

Canadian Qualifications

Canadian MTO Certification

BARGRIP

Canadian MTO Certification

BARSPLICER XP

Canadian MTO Certification

TAPER THREADED GRIP-TWIST

CSA Test Data

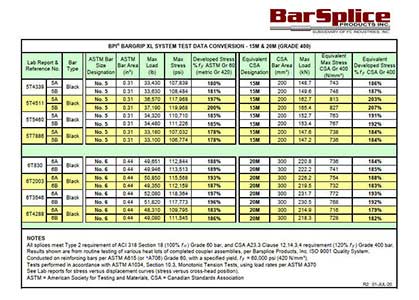

Bargrip XL

CSA Test Data

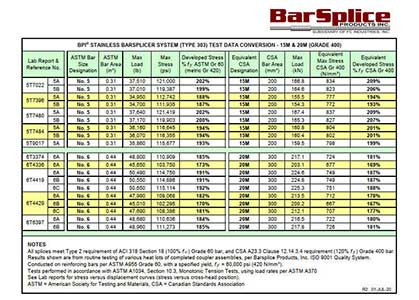

Barsplicer Stainless

CSA Test Data

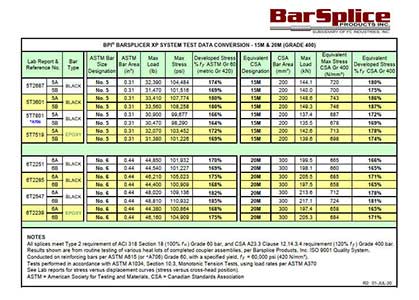

Barsplicer XP

CSA Test Data

Barsplicer DoughNUT

CSA Test Data

Buttonhead GR400

CSA Test Data

Buttonhead GR500

CSA Test Data

BPI® FITT Termination

CSA Test Data

Taper Threaded Grip-Twist GR400

CSA Test Data

Taper Threaded Grip-Twist GR500

CSA Test Data

Position Taper Grip-Twist

CSA Test Data

Taper Grip-Twist DoughNUT

CSA Test Data

Zap Screwlok SL

CSA Test Data

Zap Screwlok Type 2 GR400

CSA Test Data

Zap Screwlok Type 2 GR500

CSA Test Data

Double Barrel Zap Screwlok

CSA Test Data

Zap T-Lok

Certifications

ISO CERTIFICATION

ISO 9001:2015

Made in the USA

We are a proud member of the Buy America Steel Products Association.

Raw materials used in BPI® products are obtained from, and processed through, BPI® qualified sources/suppliers in accordance with ISO 9001:2015. All ferrous raw materials (iron and steel) used, and their coatings if applicable, have been domestically sourced, processed and manufactured in the United States of America in full compliance with the following:

• Federal Highway Administration (FHWA) 23 USC § 313 – Buy America, 23 CFR § 635.410

• American Recovery and Reinvestment Act of 2009 Section 1605 – Buy American

• 41 USC § 8302 – Buy America

• American Iron and Steel (AIS) requirements in the EPA State Revolving Fund Programs

• Build America, Buy America (BABA) Act

Presenting at Your Location

Complete the form below, and we'll schedule a presentation at your location

Barsplice sales and engineering staff will be happy to present our coupler systems at your location. We will provide detailed information, answer questions and demonstrate our range of products.

Whether you’re a structural engineering firm, detailers at a rebar fabricator or operators in the field, we will find a convenient time to work with you!